ERP vs MRP: Key Differences Every Manufacturer Should Know

Janhavi Rege

Marketing Campaign Manager

August 27, 2025

If you’ve been researching software to streamline manufacturing and operations, you’ve probably come across two terms again and again: ERP and MRP.

At first glance, they might sound similar as both help manage resources, improve efficiency, and support decision-making. But choose the wrong one, and you could end up with a system that slows you down, drains your budget, or leaves you stuck with data silos.

While they share some common ground, the difference between ERP and MRP lies in how they support operations, scale, and long-term strategy. Knowing which one fits your business today (and where you want to be tomorrow) can save you time, money, and plenty of frustration.

In this article, we’ll break down what MRP and ERP are, their pros and cons, when each makes sense, and how to decide which is the better fit for your organization.

-

MRP (Material Requirements Planning): A system designed primarily for planning materials, inventory, and production schedules to meet manufacturing demand.

-

ERP (Enterprise Resource Planning): A broader integrated business management platform that connects multiple departments (finance, HR, supply chain, production, CRM, and more) into a single data ecosystem.

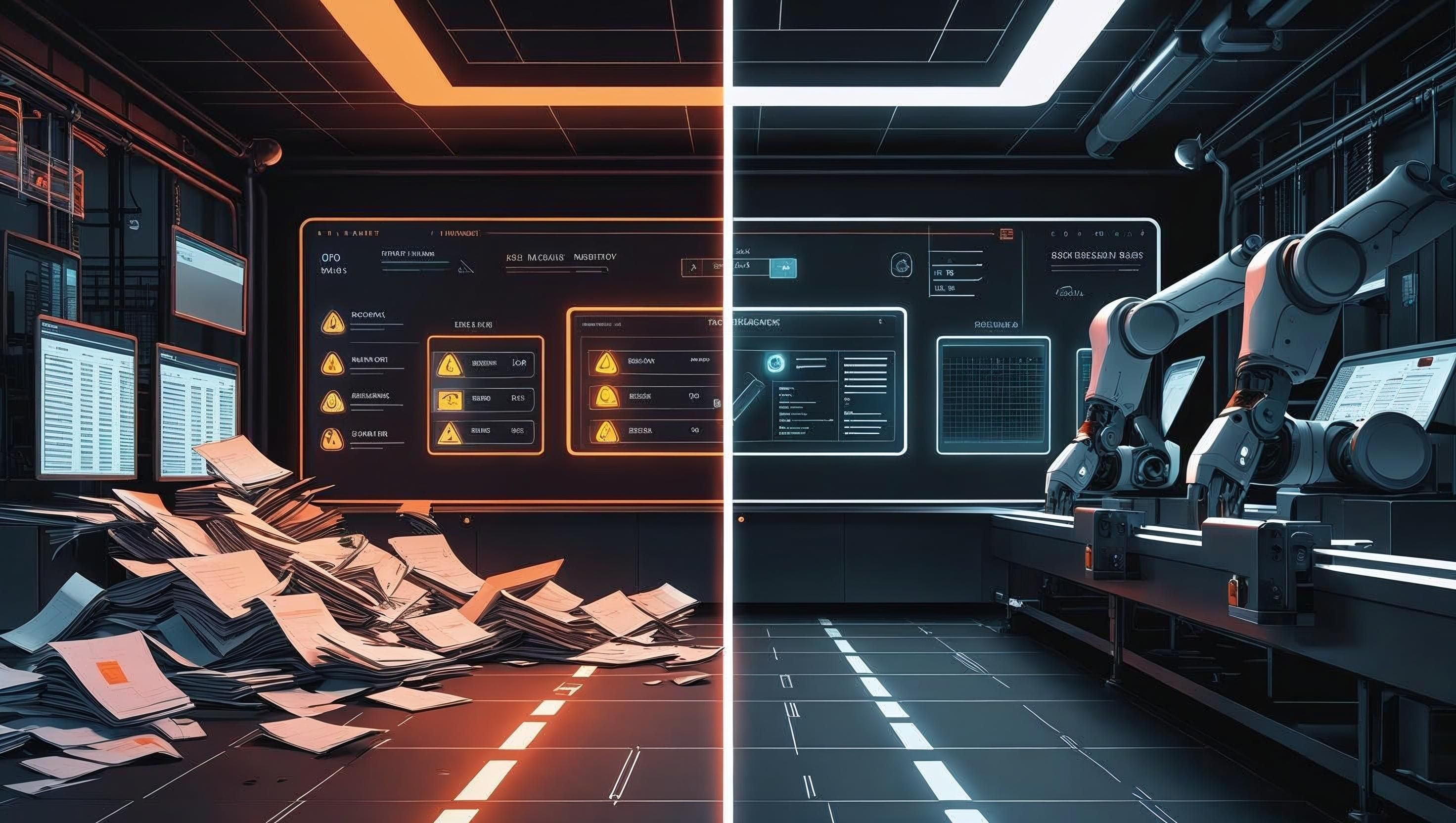

Think of MRP as a sharp, specialized tool, and ERP as a complete toolbox. We will help you understand the key contrasts in manufacturing resource planning vs enterprise resource planning, so you can make an informed choice.

MRP (Material Requirements Planning) is a software system designed primarily for inventory and production planning. It answers three critical manufacturing questions:

-

What materials are needed?

-

How much is needed?

-

When is it needed?

Core Function

At its heart, MRP ensures that manufacturing has the right materials, in the right quantities, at the right time. It schedules production runs, manages inventory levels, and helps avoid delays caused by missing components.

Typical Users & Industries

MRP systems are common in:

-

Small to mid-sized manufacturers

-

Single-location factories

-

Industries with predictable production processes (e.g., furniture manufacturing, basic electronics, textiles)

Pros of MRP

-

Laser focus on production and inventory

-

Lower upfront cost compared to ERP

-

Simpler to set up and manage

-

Excellent for just-in-time production

Cons of MRP

-

Limited scope as it focuses only on production and inventory

-

Often operates in silos, with limited integration to finance, HR, or customer management

-

Can’t provide a full picture of business performance

ERP (Enterprise Resource Planning) is a broader, integrated business management platform. It connects multiple areas of a business not just production, but also finance, HR, sales, procurement, customer service, and supply chain into a single centralized system.

Core Function

ERP ensures that every part of your organization works from the same set of real-time data. This means your operations, finance, and customer service teams can see what’s happening in production and vice versa.

Typical Users & Industries

ERP is popular among:

Typical Modules

-

Finance & accounting

-

Human resources

-

Supply chain management

-

Customer relationship management (CRM)

-

Manufacturing (including MRP functionality)

-

Project management

Pros of ERP

-

End-to-end visibility across the business

-

Real-time reporting for faster decision-making

-

Reduces manual data entry and duplication

-

Scales with your business growth

-

Supports multiple departments and processes in one platform

Cons of ERP

-

Higher upfront cost and longer implementation time

-

More complex as it requires training and change management

-

Overkill for very small businesses with simple needs

| Feature | MRP | ERP |

|---|---|---|

| Scope | Inventory & production planning | Finance, HR, SCM, CRM, and production |

| Data Integration | Limited, production-focused | End-to-end integration |

| Cost | Lower upfront | Higher upfront, broader ROI |

| Implementation Time | Shorter | Longer |

| User Base | Production & inventory teams | Entire organization |

| Best Fit | Small, single-process manufacturing | Growing or complex businesses needing full visibility |

| Scalability | Limited | High |

| Integration Effort | Minimal IT involvement | Requires significant coordination across departments |

| Maintenance Needs | Simple updates, fewer IT resources needed | Ongoing updates, training, and IT support expected |

When comparing ERP benefits over MRP, ERP clearly delivers a strategic edge for businesses aiming to grow and innovate.

ERP Benefits Over MRP:

-

Holistic Decision-Making: ERP provides financial, operational, and customer data together, helping leaders see the full picture.

-

Improved Collaboration: Cross-department visibility eliminates miscommunication between production, sales, and finance.

-

Scalability: As your business expands, ERP can handle new locations, products, and markets without the need for separate systems.

-

Customer Experience: Integrated CRM features mean better order tracking and communication with clients.

-

Regulatory Compliance: ERP systems often include compliance features for finance, HR, and manufacturing.

-

MRP Scenario: A small custom furniture maker uses MRP to ensure wood and hardware arrive on time for each project. The business is small enough that accounting is handled separately in QuickBooks, and sales are managed manually.

-

ERP Scenario: A multinational electronics manufacturer uses ERP to manage complex supply chains across continents, link sales forecasts to production planning, and ensure HR, finance, and procurement all have real-time access to the same data.

Despite ERP’s advantages, MRP still has its place. It’s the right choice if:

-

You run a small shop/business with a limited budget.

-

Your focus is only on production efficiency.

-

You don’t need complex integrations with finance, HR, or CRM.

-

Your production processes are predictable and stable.

Choosing the right system depends on your current needs and future plans.

Key Decision Factors:

-

Company Size & Complexity: Larger and more complex operations benefit from ERP; smaller ones may find MRP sufficient.

-

Growth Plans: If you anticipate rapid expansion, ERP’s scalability will be valuable.

-

Budget: MRP is cheaper upfront, but ERP may deliver higher long-term ROI.

-

IT Maturity: ERP requires more IT infrastructure and training.

Checklist

Here’s a quick checklist to guide your choice:

| Question | Answer | Suggestion |

|---|---|---|

| Do you need financial, HR, and sales integration? | Yes | Consider ERP |

| Is your company growing rapidly? | Yes | Consider ERP |

| Do you struggle with cross-departmental communication? | Yes | Consider ERP |

| Do you have a limited IT budget? | Yes | MRP may suffice |

| Do you require rapid implementation? | Yes | MRP may suffice |

Want to go deeper?

Use our “Is Your Business Ready for an ERP Implementation?” checklist to assess your organization’s readiness.

Download the checklistTechnology is evolving fast, and so are the expectations for manufacturing systems. If you're choosing between ERP and MRP, it’s worth thinking beyond today’s needs. These trends are already reshaping how businesses operate, and your software choice should be ready for them.

-

Cloud-based Solutions: Cloud ERP systems are reducing infrastructure costs and making remote work possible across departments. MRP tools may lack these modern deployment options or require workarounds.

-

AI and Predictive Analytics: ERPs are increasingly integrating AI to forecast demand, reduce inventory waste, and automate decision-making. If your growth plans include digital transformation, this gives ERP a clear edge.

-

IoT Integration: Real-time production monitoring via connected devices is becoming standard in smart factories. ERP systems are built to handle that data flow across functions, MRP is often too siloed to support this.

-

Subscription-based Pricing Models: Modern ERPs are now more accessible to smaller businesses with modular pricing and SaaS models. This narrows the cost gap and makes ERP adoption more viable than it used to be.

If you’re making a decision with the next 3–5 years in mind, these trends tip the scale toward ERP, especially if flexibility, connectivity, and data-driven growth are on your radar.

ERP vs MRP: Final Takeaway

Both MRP and ERP are powerful tools but they’re not interchangeable.

-

MRP is like a precision tool: focused, cost-effective, and great for small-scale production planning.

-

ERP is the full workshop: it handles production but also integrates every other business process.

If your business is small, stable, and production-focused, MRP can serve you well. But if you’re planning for growth, complexity, and the need for total visibility, ERP is the better investment.

The right choice comes down to where your business is today and where you want it to be tomorrow.

Need a clear plan before choosing ERP?

Our free guide, “ERP Implementation: Your Honest Guide to a Stress-Free Rollout”, walks you through every stage, from vendor selection to user training.

Download the guide

Janhavi Rege

Marketing Campaign Manager

Janhavi is a Marketing Campaign Manager at Era Consulting Group, where she has led strategic marketing initiatives for the past two years. With over six years of experience in the B2B technology space, she specializes in planning and executing integrated campaigns that drive business growth. Her expertise includes marketing automation, content creation, lead generation, and paid advertising.

Follow Janhavi Rege