Why Real-Time Visibility Is the Biggest Challenge for Distribution and Logistics in 2026

Oussama Nait-Zlay

Content Marketing Manager

December 1, 2025

If you spend your days juggling orders, stock levels, suppliers, carriers, and customer expectations, you’ve probably felt it already. Something shifted these past few years. It’s not just more orders or quicker delivery promises. It’s the pressure to see everything. Every carton, every route, every delay, every hiccup. People want information, and they want it instantly.

And you know what? So do the teams running distribution and logistics operations. Because, honestly, how do you solve problems you can’t fully see?

Let me explain what’s happening, why real-time visibility became the biggest challenge for distribution and logistics, and why companies everywhere are taking another look at their systems, especially their ERP stack. It’s about creating a system that actually works together instead of operating like a dozen islands that barely speak to each other.

Let’s walk through it.

A New Year, A New Set of Pressures

If you talk to distribution managers or listen in on logistics forums, you’ll hear the same concerns repeating. Orders are more frequent but smaller. Deliveries need to be faster. Customers want tracking updates like they’re following a food delivery app. And warehouses? They’re dealing with seasonality, demand spikes, supply delays, transportation shortages, and sometimes all of it at once.

Now add the complexity of multi-location operations. One warehouse carries product A, another one carries product B, and a third location receives partial shipments that need to be redistributed. Someone somewhere tries to update a spreadsheet, another person is refreshing a carrier dashboard, and someone else is calling a supplier to ask where their shipment went.

It’s a lot… and none of it is getting easier. No surprise then that 57 % of supply chain professionals say the lack of visibility is the biggest single challenge in their operations.

A growing number of companies are realizing something simple yet slightly uncomfortable. The lack of real-time visibility isn’t just a minor operational issue. It’s what slows everything down. It influences costs, stock accuracy, customer satisfaction, and even team morale. When people work without visibility, they work in stress-mode. And that’s not sustainable.

What’s Really Driving the Visibility Problem?

To understand why visibility is suddenly the challenge, it helps to look at the forces pushing everything forward. Some are predictable. Others… not so much.

1. Customers expect constant updates

A distributor in 2012 could ship a pallet and the customer was happy as long as it showed up. Today, the same customer is refreshing tracking links like they’re following a parcel from Amazon.

People want to know:

-

When it left the warehouse

-

When it’s arriving

-

What’s delayed

-

How to contact someone if things go sideways

And if you can’t provide that? Someone else likely will.

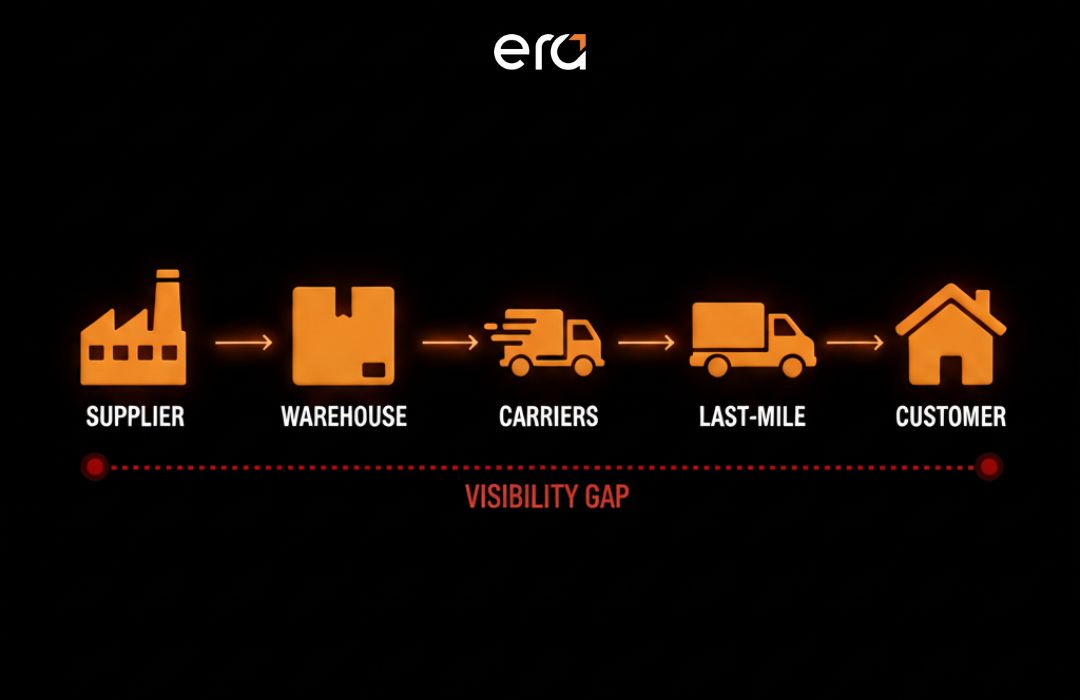

2. The rise of last-mile complexity

Last-mile used to be a simple step. Now it’s a whole universe. Micro-fulfilment, regional hubs, alternate carriers, same-day options, in-store pickups. All these routes create a maze of data points that need real-time updates. Otherwise, you get delays or missed handoffs that cost you money and credibility.

3. Multi-location operations stretched thin

Companies want to grow. Naturally. But growth without visibility creates chaos.

Imagine running three warehouses with three different systems and expecting consistent results. It’s like having three teams play the same game without the same rulebook.

4. Rising cost-to-serve

Fuel, labor, packaging, carrier fees… everything crept up.

Suddenly, knowing exactly where you lose time or money became essential, not optional.

Visibility became the only way to manage costs without cutting quality.

5. Data trapped in disconnected systems

This one hurts the most.

It’s not that companies don’t have data. They have tons of it.

The real issue is that the data lives everywhere:

-

WMS systems

-

Accounting software

-

Spreadsheets

-

Supplier emails

-

Logistics portals

-

Carrier dashboards

-

Inventory tools

-

Mobile apps

When the information is scattered, the truth becomes blurry.

Where Most Distribution and Logistics Teams Start Feeling the Pain

If you’re working in operations or planning, the pain points are probably pretty familiar. Sometimes they show up quietly. Sometimes loudly.

1. Inventory accuracy drops

You think you have 24 units in stock. The system says 24.

But when someone goes to pick them, only 17 are actually there.

One missing box creates a ripple effect that impacts planning, customer promises, and replenishment.

2. Deliveries get delayed for reasons no one can explain

A carrier says the pallet was picked up.

Your system says it wasn’t.

The customer wants answers.

Your team checks three different sources.

Eventually someone finds the truth… but by then, energy has been wasted, and stress is up.

3. Planners work with outdated information

Demand changes quickly. Supply changes even faster.

But if your data doesn’t update in real time, planners can’t respond.

It’s like steering a moving car with yesterday’s map.

4. Manual processes take over

When systems fail to speak to one another, people compensate.

They run reports manually.

They send emails.

They copy-paste data between tools.

It works… until it doesn’t.

5. Teams lose visibility of incoming supply

You can’t plan if you don’t know when goods will arrive.

And late surprises? They cost a lot.

Let’s Talk About the Real Impact

These pain points aren’t minor annoyances. They shape everything. When visibility breaks, operations slow down. And when operations slow down, costs rise.

Here are some consequences companies often underestimate:

-

Stockouts create missed sales opportunities

-

Overstock ties up capital

-

Delayed orders damage customer relationships

-

Teams spend time on tracking instead of improving operations

-

Planning becomes reactive instead of predictive

Repeated firefighting is exhausting. It drains time, money, and patience. Which brings us to the question many companies are now asking: So what’s the way forward?

What Modern Companies Are Doing Differently

Real-time visibility isn’t something you “add” like a new shelf in the warehouse. It comes from connected systems that share data instantly and consistently. Most companies don’t need twenty new tools. What they really need is a unified core that handles operations and links everything else together.

This is where more teams are exploring modern ERP systems tailored for small and mid-sized businesses. And yes, Microsoft Dynamics 365 Business Central sits right at the center of these conversations.

Curious about how businesses structure a modern ERP project?

Our ERP Implementation Guide walks you through the key stages, common pitfalls, and practical steps companies follow when upgrading their systems. It’s clear, simple, and designed for teams that want to improve operations without getting lost in technical details.

Download the free guideHow a Connected System Like Microsoft Dynamics 365 Business Central Helps Visibility Recover

If we keep it simple, visibility comes from two things:

-

Real-time data

-

A unified view of the business

Business Central brings these pieces together by connecting purchasing, inventory, sales, warehousing, and finance on one platform that updates instantly.

Here’s how it helps distribution and logistics teams regain control.

1. A single source of truth for inventory

No more comparing spreadsheets with system numbers. Everyone sees the same data, updated in real time across all locations.

If Warehouse A sells 6 units, Warehouse B sees it instantly. If purchasing receives a partial shipment, planning knows immediately. If a back-order is resolved, customer service can respond within seconds.

2. Smooth communication between warehouse, purchasing, and sales

Dynamics 365 Business Central removes the bottlenecks by letting teams share information without jumping between tools. Movements update in the same system. Replenishment triggers automatically. Salespeople have live availability without calling the warehouse.

3. Integration with logistics carriers and tracking tools

This part helps a lot. Many distribution teams rely on several carriers. Dynamics 365 Business Central can integrate with those systems so you get status updates, tracking links, and delivery confirmations directly in your ERP.

4. Real-time planning and forecasting

When your system knows what’s coming, what’s delayed, what’s low, and what’s blocked, planners can act sooner. Sometimes hours sooner. And in logistics, a few hours can change everything.

5. Better cost-to-serve visibility

You can track costs per SKU, per route, per customer. That helps leaders understand where money is being lost or where small changes might produce noticeable savings.

6. Add-ons and warehouse extensions

For companies with more advanced needs, Dynamics 365 Business Central integrates with WMS systems, barcode scanners, handheld devices, shipping software, and supply chain tools. Instead of replacing everything, BC becomes the foundation that ties it all together.

A Quick Detour: Why Real-Time Matters More Now Than Before

Sometimes people ask: “Why is real-time so critical now? We’ve always had delays and warehouses still functioned.”

That’s true. But operations used to move slower. Customers used to be more patient. Data used to be simpler.

Today, everything accelerates. Delays compound quickly. And competition is too high to make decisions based on yesterday’s numbers.

Real-time visibility isn’t a luxury, but more the difference between keeping up and falling behind. And honestly, it gives peace of mind. Knowing that the information in your system reflects what’s actually happening feels like lifting a weight off your operations team’s shoulders.

So, Is Visibility Just a Technology Problem?

Not exactly. Technology is part of it, but visibility is also a process problem.

You need:

-

Clear workflows

-

Accurate data entry

-

Standardized communication

-

Clean inventory practices

-

Integration between systems

You can have the best ERP in the world, but if the warehouse still picks without scanning or if receiving doesn’t log partial shipments, visibility will remain blurry.

That’s why companies are revisiting not just their tools, but their entire process flows.

Business Central supports both the structure and the discipline needed to get visibility right.

Why This Challenge Matters for 2026 and Beyond

Logistics volatility isn’t going away. Neither is the demand for instant updates.

As supply chains stretch across more locations, as companies grow, and as customers expect transparency, visibility becomes the element that separates organized distributors from overwhelmed ones.

Better visibility leads to:

-

Fewer surprises

-

Reduced costs

-

Happier customers

-

Less stress for teams

-

Stronger planning

-

Faster decisions

-

Improved profit margins

If visibility was once a helpful feature, it’s now a competitive differentiator.

A Final Thought Before We Wrap This Up

Real-time visibility isn’t a trend that will fade next year. It’s becoming a core expectation. If distributors and logistics teams want smoother operations, stronger planning, and less time chasing information, they need systems that talk to each other without friction.

And while Microsoft Dynamics 365 Business Central won’t magically solve everything, it gives distribution companies a foundation that many have been missing. A platform that actually reflects what’s happening on the warehouse floor. A system that links purchasing, inventory, logistics, and sales. A tool that removes confusion and brings clarity.

If you’re starting to feel the visibility gap grow inside your operations, you’re not alone.

Most companies are facing the exact same struggle, and many are now preparing to take the next step.

What does “real-time visibility” mean in distribution?

Real-time visibility means having accurate, up-to-date information on inventory, orders, shipments, and delivery status as they move across the supply chain. Instead of depending on delayed updates or manual tracking, teams can see what is happening as it happens.

Why is visibility becoming harder to maintain?

Operations are more complex than before: multiple warehouse locations, several carriers, last-mile partners, fluctuating demand, and systems that don’t talk to each other. All these elements create blind spots that slow down decision-making.

Do companies need an ERP or a WMS to improve visibility?

It depends. Many distributors benefit from using both. A WMS manages execution inside the warehouse, while an ERP like Microsoft Dynamics 365 Business Central connects inventory, purchasing, finance, sales, and logistics. The strongest visibility comes when both systems work together.

How does Microsoft Dynamics 365 Business Central improve visibility?

Business Central centralizes operational data, updates inventory in real time, connects directly with carriers for tracking, and offers a unified view of supply chain activities. This helps reduce surprises, improves planning, and speeds up decisions across distribution operations.

Oussama Nait-Zlay

Content Marketing Manager

Oussama is a technology content expert at Era Consulting Group. He focuses on making complex topics related to ERP and enterprise technologies accessible, helping organizations fully leverage digital innovations. He brings several years of experience in the SaaS and technology industries, notably with companies such as Zoho and ManageEngine.

Follow Oussama Nait-Zlay