7 Signs Your Current System Is Slowing Down Your Production (and How to Fix It)

Oussama Nait-Zlay

Content Marketing Manager

August 13, 2025

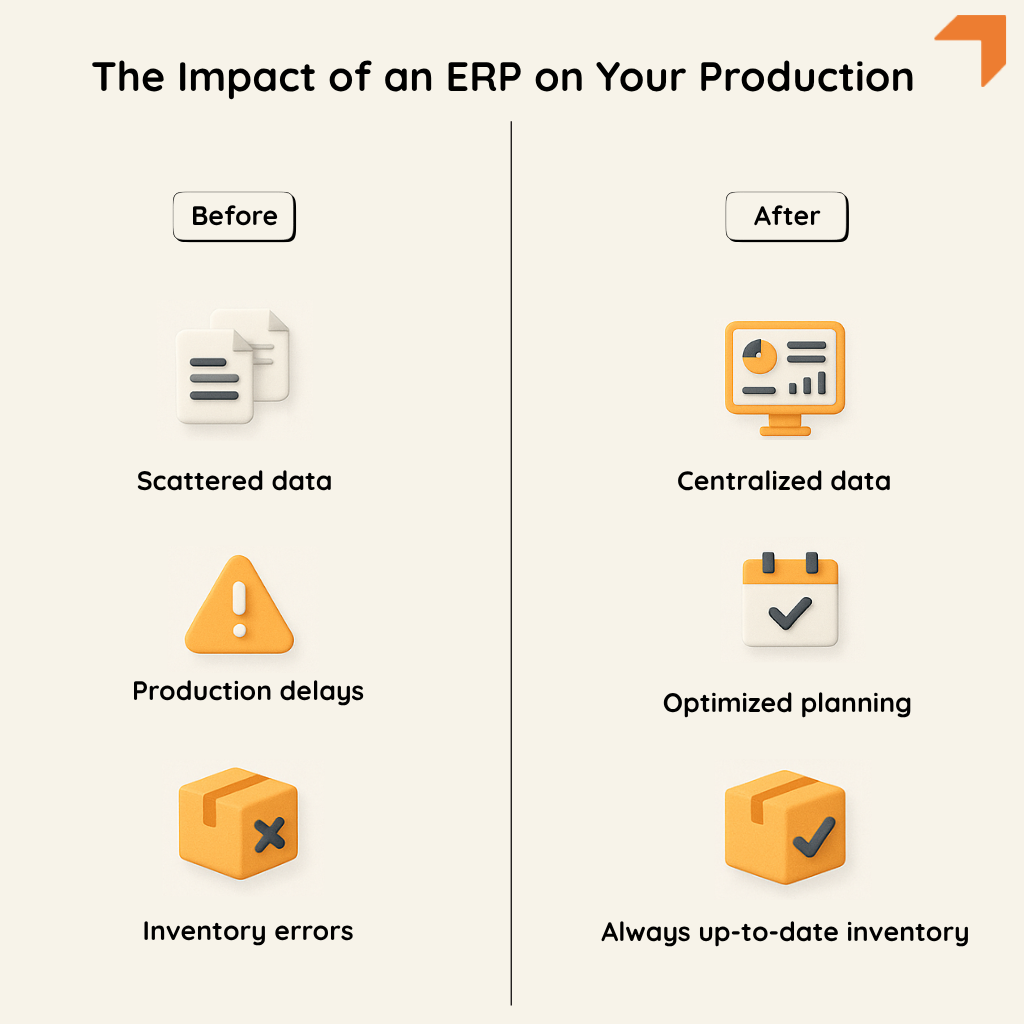

You know that feeling when everything seems to be running smoothly… until the slightest disruption throws the whole operation into chaos? Production delays, stock errors, back-to-back crisis meetings… This isn’t just bad luck. Often, the real problem doesn’t come from your teams or even your strategy, but from the systems you use every day.

In many manufacturing plants in Canada, operations still rely on makeshift Excel spreadsheets, outdated software, or even limited ERPs, often accompanied by multiple applications that don’t communicate with each other. The result? No data centralization and fragmented visibility that slows down decision-making.

So how do you know if your systems are actually slowing down your production? Here are 7 telling signs that your organization would greatly benefit from considering a modern manufacturing ERP, and more importantly, what you can do to turn things around.

1. You’re Still Juggling Dozens of Excel Files or a Too-Limited ERP

You know those spreadsheets that multiply for planning, inventory tracking, order management… or those ERPs so restricted they constantly require manual workarounds due to a lack of full integration. If your teams spend more time searching for the right information than actually producing, it’s a clear sign that your system isn’t keeping up with your ambitions.

2. Your Production Lead Times Are Getting Longer… and You Don’t Really Know Why

When an order is delayed, nothing is more frustrating than not knowing why. Is it a supply issue? A planning error? A bottleneck on a specific machine? If getting an answer requires multiple phone calls and a “tour of the shop floor,” it’s a sign that your systems lack overall visibility into production management.

3. Inventory Errors Are Costing You and Eating Away at Your Margins

Inventory marked as available… but nowhere to be found when production starts. Or worse, overstocking that ties up cash flow and clogs your warehouses. These errors aren’t harmless, they eat into your margins, create emergency orders, and frustrate your customers. A manufacturing ERP centralizes data and drastically reduces this type of issue.

4. Your Teams Spend Their Days Putting Out Fires

If every day feels like a marathon of “crisis management” rather than a well-oiled routine, something isn’t right. Modern systems should help you anticipate problems, not just react to them. When you’re constantly chasing after the unexpected, it’s often because the information arrives too late, or isn’t reliable.

5. Communication Between Departments Is Painful and Slow

Production, purchasing, sales… each department has its own software, its own numbers, its own priorities. And to share information, you rely on emails, meetings, or printed reports. The result? Lost time and decisions made on partial, or even outdated, data.

6. You Feel Like Your Systems Are Holding You Back More Than Helping You

When a simple change in scheduling or a bill of materials requires complex manipulations (or help from IT), it’s a sign that your tools are no longer adapted. Even with an existing ERP, if every adjustment requires costly custom developments or if your system can’t keep up with your growth, it’s slowing you down.

7. You Don’t Have a Clear View of Your Actual Costs

Between purchasing, production, scrap, remainders, and overtime, getting an accurate picture of your margins should be simple… but if it takes you days (or even weeks) of manual compilation, there’s a problem. Without reliable, accessible data, making the right decisions at the right time becomes impossible.

How to Get Your Production Back on Track

The answer isn’t to “work harder” or to add more tools. What you need is a global view of your operations and processes that adjust in real-time, without relying on scattered files or endless meetings.

That’s exactly what a modern ERP like Microsoft Dynamics 365 Business Central delivers. Whether you’re currently using a patchwork of software or a limited ERP that has reached its limits, this platform provides a scalable solution designed to support the growth of Canada’s manufacturing SMBs.

With Dynamics 365 Business Central, your data (inventory, purchasing, production, sales) is centralized and updated continuously. This means you always know the status of your orders, where your raw materials are, and the impact of each decision on your costs and lead times.

And contrary to popular belief, implementing an ERP doesn’t mean a never-ending project or a loss of flexibility. Solutions like Dynamics 365 Business Central are connected, scalable, and built for your teams, not just for your financial analysts.

Ready to Take the Next Step?

If you recognized yourself in several of these signs, it may be time to seriously evaluate solutions that can truly support your growth.

We’ve prepared an exclusive comparison guide that puts Microsoft Dynamics 365 Business Central side by side with other popular ERPs used by manufacturers in Canada. In just a few minutes, you’ll have a clear view of the strengths, limitations, and key differences to make an informed decision.

Want to compare the top ERP options for manufacturers?

We've created a free guide that compares Microsoft Dynamics 365 Business Central with SAP Business One, Oracle NetSuite, and Epicor Kinetic, so you can make the right decision based on your real needs.

Download the ERP Comparison Guide

Oussama Nait-Zlay

Content Marketing Manager

Oussama is a technology content expert at Era Consulting Group. He focuses on making complex topics related to ERP and enterprise technologies accessible, helping organizations fully leverage digital innovations. He brings several years of experience in the SaaS and technology industries, notably with companies such as Zoho and ManageEngine.

Follow Oussama Nait-Zlay